The Environmental Impact of 3D Printing

An eco-friendly, or earth-friendly world, is something everyone’s talking about these days. Yet despite the discussion, there’s still a lot more talk than there is action. We’re a long way off from achieving realistic goals in protecting the environment in a major way. This is the challenge of our lifetime. The passion is more evident with younger generations than their older counterparts. 3D printing is an area that looks promising going forward, but more research is necessary. Right now, it’s not the perfect solution to clean manufacturing, but it could be. In this piece, we look at this exciting new technology and how may it help to produce and create things in a clean and non-destructive way.

3D Printing in a Nutshell

3D printing, AKA additive manufacturing, allows users to print something (an idea) from thin air. OK, it’s not quite that spectacular, but it’s close to it. Modern 3D printing lets us turn graphic designs into actual physical objects that we can hold in our hands. These are two-dimensional designs created on a computer screen using special software. Once the user uploads their file to the printer, the machine gets to work. It builds the 3D object by extruding material onto a build platform in progressive layers. There’s more to it than that, but this is pretty much 3D printing in a nutshell.

3D printers and printing technology has been around for about 30 years now. Even so, it’s only caught the public’s attention in more recent times. This is thanks to superior machines, improved printing materials, and lower costs.

An Eco-Friendly World in 3D – Myth or Reality?

Green living, eco-friendly, carbon footprint, and other such terms, used to be little more than buzz words. This is no longer the case. We live, and always have lived, in a finite world. If human behavior doesn’t change, and change soon, we’ll destroy the planet we call home. This means we have to come up with new and innovative ways to produce items that are safe for the environment. It’s no longer a choice. The time has arrived where we have to conserve and protect life and valuable resources. So how does 3D printing fit into the bigger, global picture? Keep reading to find out how this amazing technology will help to provide us with a cleaner, greener way out.

Despite its 30 year history, 3D printing technologies are still evolving. That’s both good news and bad news. It’s bad because we’re not there yet, and it’s good because the future looks bright. We’ll start by looking at the current setbacks and then move on to the future potential of 3D printing.

The Not So Good News

The not so good news is that 3D printing right now is not what you might call eco-friendly. Here are the three main disadvantages of this technology:

- 3D printing takes a lot of energy to produce items

- A lot of 3D printing relies on plastic materials to print

- The 3D printing process produces fumes with toxic by-products

We’ll now break each of these down and put them into some perspective.

1) 3D Printing Uses Lots of Energy

The research done on this so far is not 100% conclusive. What researchers can agree on, though, is that 3D technology is energy-hungry. Some argue that it uses more power than conventional drilling and milling machines. One team of researchers at Loughborough University in the UK did their own study. The ‘Atkins Project‘ produced similar objects using the different technologies. Their findings were not good for 3D printing. In fact, some 3D printing processes used 50-100 times more electricity than injection molding machines.

Worth noting is that energy alone is not the full picture. There’s more to an overall carbon footprint than electrical machine power. Other considerations include:

- The manufacturing process

- Raw materials used

- Location of the manufacturer

- Transportation mode used for distribution

The findings of the ATKINS team point out that the additive manufacturing process didn’t have the lowest carbon output at every step of the supply chain. 3D printing did fare better at the material production stage. The reason for this was because it used less material and produced less waste overall. Some 3D models need support materials though, which the user discards at the end of the printing process. In the case where a printed part uses support materials, the wastage then goes up.

What we can take from this, to date, is that 3D printed products are able to produce low carbon parts, but only at the material-production stage, not the energy-production stage—yet. Yes support material waste can be something of an issue, but it’s not the main concern from an environmental standpoint. That concern remains with the energy consumption.

What the Science Says

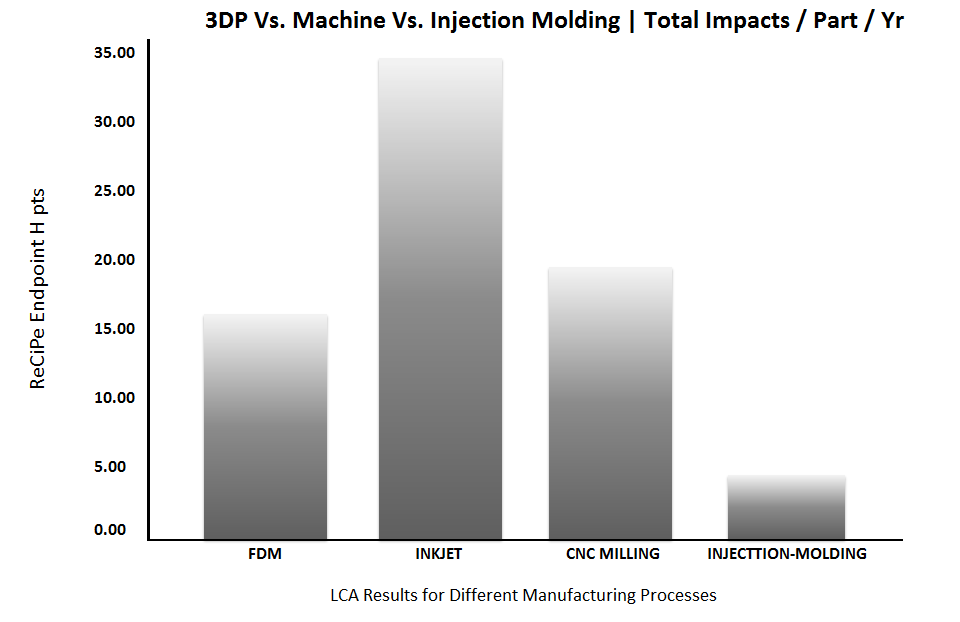

The chart below looks at the environmental impact from four types of machine:

- 3D FDM printer

- Inkjet printer

- CNC milling machine

- Injection Molding

The more points there are, the higher the environmental impact was in this test. This graph illustrates each of the machines producing the same parts constantly (24/7). This is a general guide on the Life-Cycle Assessment (LCA). With regards to 3D printing technologies, there’s still a way to go.

2) 3D Printing Uses Lots of Plastic Materials

Another setback to 3D printing’s carbon footprint is with the plastic materials it uses. The majority of widely used plastic filaments are eco-unfriendly. Unfortunately, high-end 3D printers used in industries leave behind considerable amounts of plastic by-products. None of these by-products are reusable, hence the current problem. There is, however, one plastic material that does show great promise, and we’ll look into that a little later.

3) Secondhand 3D Printing Fumes

Dr. Brent Stephens, Assistant Professor from the Illinois Institute of Technology, Chicago, led a study that looked into fumes produced by 3D printing. His team researched the potentially harmful emissions created by printing with plastics (also called 3D inks). Their findings found that the materials held toxic by-products when heated at high temperatures. This doesn’t come as any real surprise as all kinds of heated materials produce some level of toxic emissions, including cooking. In fact, the emissions produced by heating these plastic materials were on a par with those created by cooking indoors. Even so, if 3D printing has a future on a mass scale, there needs to be more research and innovation. Improvements in this area are already happening, which you can read about below.

The Good News

Despite the concerns mentioned above, the eco-friendly potential for 3D printing looks good. This is when compared to the conventional manufacturing processes used in mass production. 3D printing is not perfect yet. But unlike other technologies, it still has lots of potential for future improvements, and that’s the good news. But manufacturing doesn’t start and end with only power consumption.

A product’s carbon footprint takes on many factors, including (in no particular order):

- Product life cycle

- Extraction of raw materials

- Manufacturing

- Product assembly

- Product refining processes

- Product use(s)

- Maintenance

- Product durability

- Product life cycle

3D printed parts are proving to have considerable advantages over conventional manufacturing processes. Because there’s little waste in 3D printing, there’s no need for excess cutting, drilling and milling. Less refining and assembly also means a reduction in storage before sale and distribution. This is yet another area that reduces the overuse of resources on a mass production scale.

The Toxic Life Cycle of a Product

Conventional manufacturing goes through many harmful processes. This usually starts with the extraction, preparation and delivery of raw materials. As we live in a throwaway society, lots of short-lived products are soon disposed of. Mining raw materials and burying their by-products are both things that contribute toward environmental pollution. Discarding products at the end of their life cycle often causes the most environmental harm of all. The dumping of toxic waste already wreaks havoc with air, land and sea—in a major way.

3D Printing’s Eco-Friendly Material

Right now there are two main plastics used in everyday 3D printing. One is acrylonitrile butadiene styrene, better known as ABS. The other, and the one we’ll focus on, is polylactic acid, or PLA. The industry refers to these as ‘thermoplastics,’ which means they melt and mold easily.

The corn-based eco-friendly plastic, PLA, is leading the way. It’s a renewable type of thermoplastic material. PLA produces considerably less toxic emissions during the printing stage than others, but that’s not all. There’s even less waste product with PLA when used as a filament for 3D printing. It’s also better at the disposal stage at the end of a product’s life cycle. This is why it’s currently, and will continue to be, the most popular choice over other 3D printing materials like ABS.

Other widespread, earth-friendly 3D printing materials to look out for in the future may include:

- Bio-plastics

- Powders

- Resins

- Acrylates

- Wax

- Others (watch this space)

Can 3D Printing Help to Save the Environment

It’s the hope of innovators and scientists to correct all these current problems with future 3D technology. 3D printing has come a long way in recent years, but many say it’s still at the warming up stage. Imagine a world where eco-friendly 3D printed parts produced all we could ever need. And imagine that with minimal impact to the planet and everything that lives on it.

Could 3D printed electric cars, buildings, TV sets, washing machines and computers be just around the corner? You might think it sounds a bit farfetched, but then so did all other impressive technologies that have now become commonplace. Talk to anyone who works in the research and development departments of 3D printing, in all its forms, and feel the buzz. As far as they’re concerned, there’s unlimited potential just waiting for someone to tap into.

Smarter 3D Printing

Until the technology evolves and we’re able to print in 3D with less damage to the environment, there are other various workarounds that can help. One approach to reduce the carbon footprint is to use less energy (see below), and the other is through the use of smarter materials or filaments.

- Print objects with hollow parts

- Change part orientation while printing

- Print more than one part at a time on the printer bed

A hollow part will need less material and therefore print faster. Complex parts may need support materials, but it will still mean faster print times and less emissions overall. Laying tall parts on their side is another way to speed up the printing process and reduce or eliminate the need for support materials. And for printers that have a good sized print bed, or print platform, it’s possible to print several parts in one hit. Let’s now look at the importance of quality 3D filaments.

Not all 3D printing materials are equal. Better materials offer the following benefits:

- Reduce resource use

- Cut down on waste

- Produce less toxicity

- Reduce energy use

PLA bio-plastic takes less energy to produce and less energy to print with. You might also want to look into printing with a special kind of wood pulp that works in conjunction with an adhesive binder. Not all printers can print with every material, so it’s important to check before investing in alternatives.

The Material Safety Data Sheet (MSDS)

You can find all 3D printer materials in the MSDS. This is helpful for protecting yourself against long-term exposure to harmful toxins. It’s also useful for choosing materials which are more eco-friendly. Without getting too technical, look for the NFPA or HMIS numbers of a filament. They inform you of any toxicity, reactivity and flammability hazards. The lower the score is, the lower the product’s toxicity levels. There’s more science behind it than that, but looking for the lowest number is enough for most home users.

Printing Your Own Products

As prices continue to fall, more people than ever before will soon be printing their own custom products. From the comfort of home you’ll be able to design and print something you want that’s durable, light, and created with no waste. If—or indeed when—3D printing dominates manufacturing, things will start to get really interesting. We’ll see products that feel great, function better, and cost less to produce, and therefore buy. They’ll last a lot longer too, which will result in less garbage. Widespread 3D printing could also see more manufacturing returned to local communities. The savings to the environment on this alone would result in less transportation needs and costs overall.

Summing Up

Optimists will tell you that 3D printers and new printing technologies are here to stay. They believe it will change the way humans manufacture products forever. Some even think that mass production will become a thing of the past as people take to producing their own things as and when they need them. And there are those who think 3D printing will exist alongside conventional manufacturing. This group thinks it’ll offer a part solution toward greener engineering in the years ahead. You decide!

Thanks for the article, Mr. Flynt. I am beginning a new 3d scanning and 3d printing business in the Washington DC area and I’m also a part time environmentalist. It’s important to me that my new company is as responsible as possible. (recycling filament, using environmentally-friendly materials, considering the paper 3d full color printer Mcor, etc…) I’d love to hear about any other environmentally-friendly 3d printing and 3d scanning findings in the future. Again, thanks. Bruce Wyman ([email protected])

Thanks for the article! I’m part of an organization that gives workshops on 3D printing to the public and my task is to come up with workshops. I’m trying to find prints / activities that are oriented towards a less wasteful print and approach it in a way that puts those concerns to the forefront. Thank you for this resource, I will keep these points in mind

I am just entering the 3D printing world. Thanks for the informative article.